Processing Plant Overview

We have three facilities located in Ehime, Wakayama, and Tokyo that allows us to meet our clients’ needs through a variety of processing options ranging from chilled and frozen fillets to skinless loins.

Each fish is handled with the utmost care throughout the entire production process to ensure that the freshest and highest quality products are delivered to our clients. Our goal is to actualize our corporate philosophy of Making People Happy with Fish.

KAINAN SEAFOOD CENTER

Overview

The Kainan Seafood Center is ISO22000, EU/USA HACCP, and ASC Chain of Custody certified. Operating round the clock, 365 days a year, this facility continuously receives, processes, and dispatches over 2.2 million fish annually.

Equipped with advanced machinery, we can efficiently deliver seafood to customers throughout Japan and serves as the central hub for our marine products business.

Being located just 30 minutes from the Kansai International Airport, our 24-hour operation enables us to proudly export the freshest Japanese seafood overseas.

Processing Facility

Receiving of Live Fish

Adjacent to our facility, we have 40 marine pens and 6 land-based tanks for live fish. These facilities enable us to receive daily year-round shipments of fish via boat and truck from Shikoku and Kyushu.

To ensure the well-being of the fish, we carefully manage the stocking density, and the amount harvest quantities are adjusted according to the seasonal variations and water temperature.

Electrical Sedation

An electric sedation system is integrated beneath the fish landing table mat. This system applies a gentle electrical stimulation to calm the fish, reducing their agitation and excessive movement during harvest. As a result, the fish can be quickly and safely harvested ensuring optimal freshness and quality.

By employing this sedation system, we prioritize the safety of our employees while also streamlining the harvest process by suppressing the movement of the live fish.

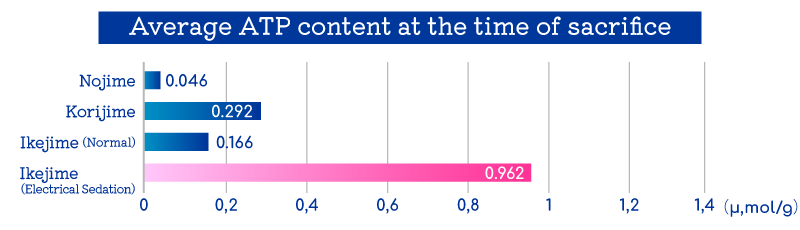

ATP (adenosine triphosphate) is an important substance related to energy in the fish’s body, and a key indicator of freshness. Ikejime is employed to preserve the ATP in the fish’s flesh. As the ATP in the body degrades, it becomes inosinic acid, a component of umami, so the amount of ATP is a decisive factor for quality.

Ikejime ・ Spinal Cord Destruction

Upon harvest and turning on the power to the electrical sedation mat, the fish are slaughtered via an automatic guilotine or alternatively, ikejime by hand. Then in order to delay the onset of rigor mortis and preserve the fish’s freshness Spinal Cord Destruction is performed on each fish.

With respect and gratitude for the fish becoming food, we strive to complete our work quickly and efficiently to reduce the fish’s stress.

Cooling ・Bleeding

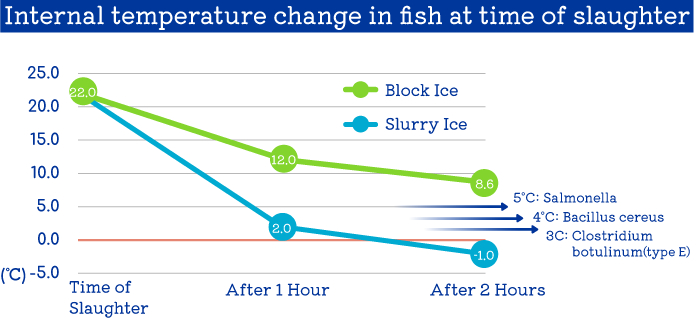

After ikejime and spinal cord destruction, the fish are immediately bled and cooled in slurry ice.

Slurry ice is a fluid mixture of small spherical ice particles, several millimeters in diameter. Its small spherical shape and large surface area, along with its high fluidity, allows it to penetrate into the fish’s intricate spaces without causing damage, enabling rapid and uniform cooling. Slurry ice is also used during processing to prevent the product’s temperature from rising and ensure proper hygiene.

Processing ・ Packaging

After bleeding and cooling, the fish are processed. The fish are processed and shipped per the customer’s request (Round, Semi-Dressed, Dressed, Fillets, & Loins). In conjunction with the receipt of live fish, our facility operates 24 hours a day, 365 days a year.

Basic work procedure consists of the removal of the scales, head, gills, viscera, various processing operations such as filleting, vacuum packaging, metal detection, boxing, and shipping. We have a dedicated machine for each process, as well as contingency plans in place to ensure that each process can be carried out manually in case of any unexpected machinery malfunctions.

Shipping

We have built a shipping system that is unbeatable in terms of freshness that allows us to deliver DAY-0 and DAY-1 fish all over Japan.

Under the slogan, “The closest to overseas!”, we provide the freshest Japanese fish to North America, the EU, the Middle East, and Asia.

Food Safety Policy & Guidelines

Food Safety Policy

Dainichi Kainan Seafood Center will continue to provide safe, reliable, high-quality fresh seafood processing.

Guidelines

Fairness and Respect: We will comply with laws and social norms, act fairly with a strong sense of ethics, and prioritize respect for human life.

Sincerity and Pride: We will always provide high-quality products and services and take pride in our work.

Ingenuity and Challenge: We will continue to take on challenges so that we may continuously seek innovative solutions.

Quality Improvement Slogan

Careful attention to each piece, Fish by Fish

2020/11/30

Dainichi Corporation, Kainan Seafood Center

Takeo Matsushima, Senior Managing Director, Center Manager

Facility

| Ice Machine | 3 |

|---|---|

| Slurry Ice Machine | 3 |

| Marine Pens | 40 |

| Land Tanks (10MT) | 6 |

| Ikejime Machine | 3 |

| Descaler | 3 |

| Gutting Machine | 1 |

| Head Cutting Machine | 3 |

| Filleting machine | 4 |

| Metal Detector | 3 |

| Vacuum Packaging Machine | 4 |

| Scale / Label Printer | 4 |

| Refrigerator / Freezer | 3 |

| Wastewater Treatment Facility | 1 |

| Various Inspection Equipment | Bacteria test equipment, temperature measurement data logger, residual chlorine concentration measurement test paper, etc. |

| Paperless Document System | Employee health check monitoring system. |

ISEKIN SHOTEN

Overview

Located in Tokyo’s Ota Market, the facility specializes in supplying fillet and loins of hamachi and madai year-round to businesses in the Tokyo area.

2 land-based tanks used for holding live fish at this facility allows us to process and deliver DAY-0 product with outstanding freshness according to our customer’s needs.

Processing Facility

This facility possesses a descaler, head cutter, skinning machine, and vacuum packaging machine. All filleting is done by hand by our skilled staff. The facility is also fully equipped with a metal detector, weight-scales, ice machine, and refrigerator.

| Descaler | 1 |

|---|---|

| Head Cutting Machine | 1 |

| Skinning Machine | 1 |

| Metal Detector | 1 |

| Vacuum Packaging Machine | 1 |

| Scale / Label Printer | 1 |

| Ice Machine | 2 |

| 10MT Fish Tank | 2 |

UWAJIMA KAIDO

Overview

Situated in Ehime’s Seiyo City, this facility employs a patented process known as Cho-Rei-Kun, that employs liquid smoke and quickly freezes the fish. We exclusively utilize farm-raised fish during their peak season. Prior to processing, the fish undergo a 16-hour destressing period. From the moment they leave the water until freezing and packaging, the entire processing procedure is completed in under 2 hours. In addition, we obtained FSSC22000 certification as of August 2022.